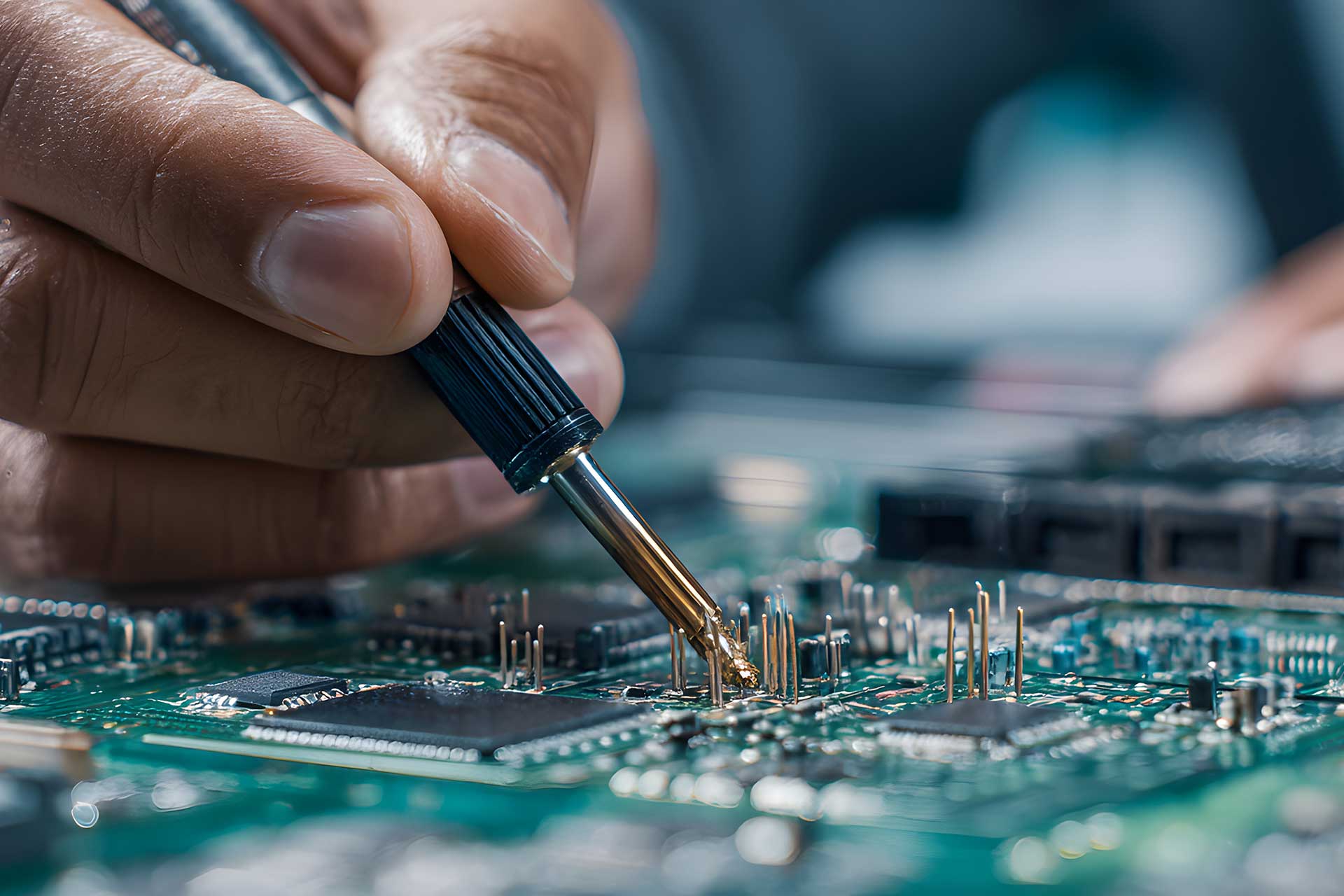

Tarapath Pty Ltd is a trusted supplier and solutions provider to the electronics manufacturing industry in Australia and New Zealand.

For over three decades, Tarapath have been delivering high-quality products, specialised equipment and tailored manufacturing solutions that help electronics manufacturers improve efficiency, reliability and production capabilities.

At its core, Tarapath operates as an importer and distributor of electronics production components and systems, with a broad product range that includes hardware used across printed circuit board (PCB) assembly, storage and handling, and production aids. Initially focused on PCB terminals and mounting hardware, Tarapath has steadily expanded into more complex equipment and process-oriented solutions that directly support modern electronics manufacturing workflows.

Comprehensive Range of Parts and Consumables

Tarapath’s range of products features essential parts and consumables commonly required on manufacturing floors. These include antistatic and storage products designed to protect sensitive electronic components from electrostatic discharge and environmental damage. The range includes items such as moisture barrier bags, humidity indicators and static-dissipative packaging that are vital for safe handling of electrostatic-sensitive devices.

Tarapath also supply PCB stamps and inks, PCB storage solutions, and a variety of assorted terminals used in circuit assembly and connectivity applications. These products ensure efficient workflow from component storage through assembly and dispatch stages.

Production Equipment Tools & Aids

Beyond basic parts, Tarapath offers a selection of production equipment and aids that help manufacturers streamline assembly and packaging processes. Examples include vacuum chamber sealers for protective packaging, pneumatic impulse sealers, and retractable nozzle vacuum sealers with gas purge functions for controlled atmospheric packaging.

Specialised machinery such as motorised SMD counters, component formers, and tape handling accessories support accurate counting, forming and preparation of components for assembly lines. These tools play a crucial role in maintaining quality and throughput in high-volume environments.

Low Pressure Moulding

One of Tarapath’s standout offerings is their expertise in Low Pressure Moulding (LPM) — a protective encapsulation process that serves as an alternative to traditional potting and conformal coating. Tarapath supplies both the equipment (including machines from brands like Optimel and LPMS) and materials (Henkel TECHNOMELT polyamide compounds) needed for LPM, catering to applications ranging from prototype development to high-volume production.

In addition to equipment and materials, Tarapath offers design and engineering support, tool and mould manufacturing, process training, and contract over-moulding services — enabling Tarapath clients to adopt LPM without needing to investing in their own machinery.

Custom Solutions and Full Assembly Support

For customers requiring tailored manufacturing solutions, Tarapath can integrate products, components and processes into complete assemblies, handling everything from custom metal work and cable assembly to PCB integration and final testing. This end-to-end capability makes Tarapath a valuable partner for all electronics manufacturing companies seeking both parts supply and turnkey production assistance.

Tarapath’s blend of parts supply, specialised equipment, innovation in low pressure moulding, and custom manufacturing support provides a comprehensive resource for electronics manufacturers across Australia and New Zealand.

For more information contact Tarapath today Ph: +61 3 9269 6200